Priorities for businesses have evolved, and the current global crisis has caused the supply chain industry to rethink strategies and drivers of success. The past few years have extensively covered cost optimization and delivering exceptional service levels to customers. These elements are necessary for driving process excellence and optimizing supply chain performance, but the importance of supply chain visibility is paramount. Tracking and tracing capabilities are essential for supply chain visibility and having visibility into real-time logistics operations enhances the visibility of the logistics at a granular level.

Many shippers may observe inconsistencies in the real-time duration of logistics operations and estimated durations generated by the systems. Such discrepancies can cause customer dissatisfaction in the long run due to delayed deliveries. Therefore, how can we accurately calculate the duration of these logistics operations?

Logistics operations primarily consist of numerous activities that make up the entire process. Transit, loading, unloading, Available to Promise (ATP), and lead time are a few examples of these elements that make up logistics operations. The sum of the time taken to complete these activities is the logistics operation duration. There are multiple calculation methods for loading and unloading duration in SAP TM. Our blog here focuses on a specific loading and unloading duration calculation method via BRF+ conditions, why we might prefer BRF+ conditions over other duration calculation methods based on business requirements, and its impact and benefits on the entire process.

Loading and unloading duration is the time taken for loading and unloading activities at a facility.

Loading & Unloading duration can be calculated in three different standard calculation methods as offered in SAP TM.

Here are a few examples of other calculation methods before we delve into BRF+ condition-based method.

Some loading and unloading duration calculation examples below based on rules are:

- A fixed duration can be defined for loading and unloading activities at a logistics operation location such as a warehouse, port, or rail junction.

- Another example can be a variable duration which can be defined on a per-truck basis or any type of unit

Conditions allow us to calculate the loading and unloading duration for each required document such as Freight Unit (the smallest shippable unit in SAP TM) or Freight Order (shipment document in SAP TM) and provide some flexible ways to do it. For example, a condition-based calculation method can respond to the following business requirement.

Loading & Unloading |

Weight |

15 mins |

0-10.000 LB |

30 mins |

10.000-20.000 LB |

45 mins |

20.000-30.000 LB |

According to this calculation method, the duration will be calculated as 30 mins for 13.000 LB of cargo, on the other hand, 17.000 LB of cargo will take 30 mins as well. What if I want more accurate calculation results in my ERP software based on per LB, per KG, or per pallet as a facility manager? This is possible via a “planning profile” which is a master data element in SAP TM, however, even a planning profile has a limitation. In the planning profile, any duration greater than 1 second per unit (lb, kg, etc) can be easily defined. However, loading & unloading of less than 1 second per unit is not allowed.

For instance, we’ve received a customer business requirement which was 1-hour loading & unloading duration per 10.000 lb. In addition, we’ve asked to define this 1-hour duration based on the minimum unit, in case of small shipments of a few pounds in some cases. That is where BRF+ conditions come into the picture to help us to create custom formulas without an enhancement or coding by the developers. The screenshot below shows the minimum 1 second per lb limitation in the planning profile.

A fixed duration can be defined per the requirement document. For example, 5 minutes can be defined per Freight Unit or 1 hour can be defined per Freight Order.

Now let’s consider a business requirement as loading and unloading durations need to be defined as 1 hour for every 10.000 lbs. of cargo. 3.600 seconds / 10.000 = 0.36 seconds per lb. for each Freight Unit. We will proceed with the BRF+ configuration as described in the steps below:

Create a new loading and unloading condition in NWBC and set the condition type as /SCMTMS/FU_LOAD_DURA and set the origin of the condition as “Condition based on BRF plus Expression" and hit continue

Without changing anything save the condition.

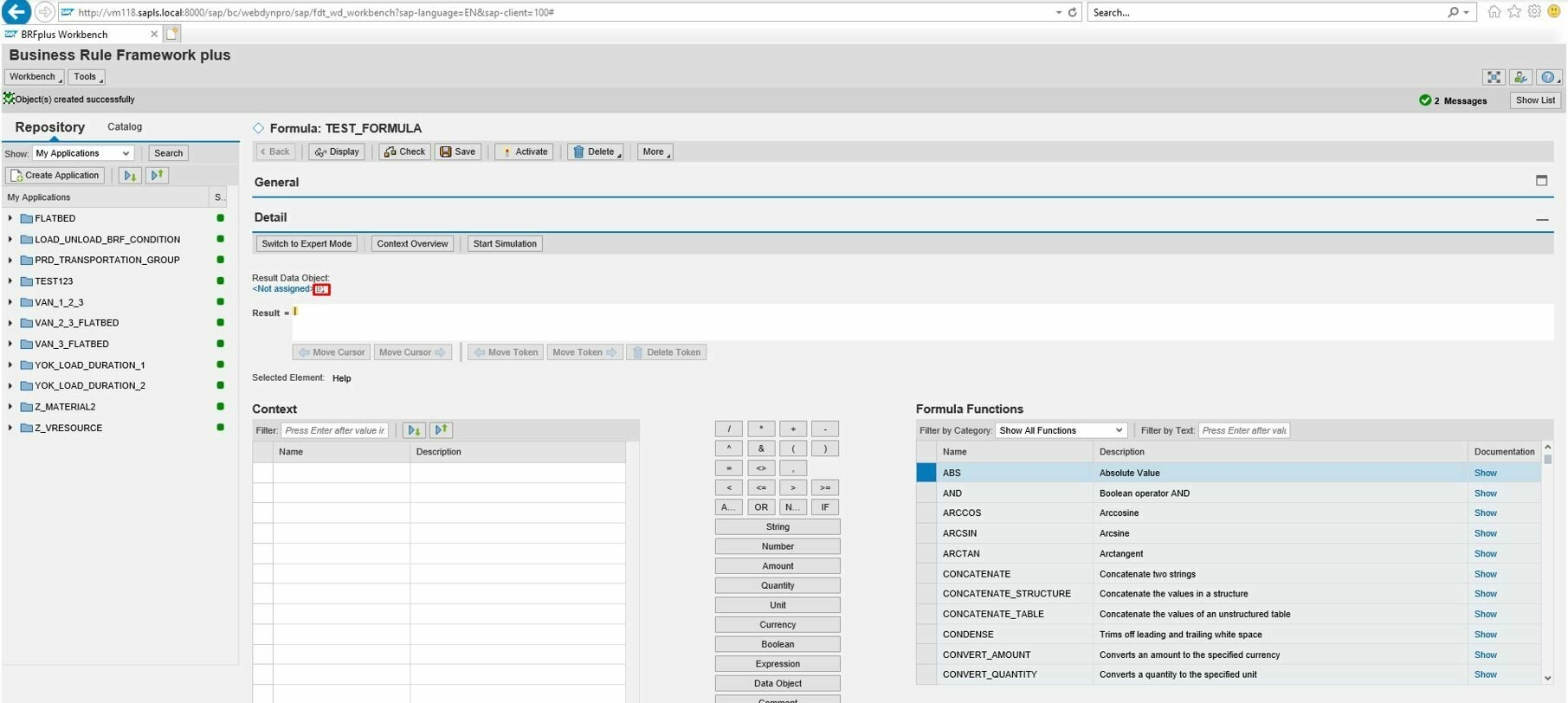

Go to t-code BRF+, and a new web browser window will pop up. A newly defined condition can be displayed on the left side.

Right-click on your newly defined condition and create a formula

Name your formula and hit the “Create and Navigate to Object” button

The resultant object needs to be assigned first. In this case, the result object will be loading & unloading duration

The same assignment needs to be done for both loading and unloading durations separately

A rule set needs to be defined. Select Rule Set Option

Create and Navigate to Object

Insert Rule and Create

The below screenshot shows the final view after completing the BRF+ condition configuration

Once the configuration steps are complete the defined BRF+ condition needs to be assigned in Planning Profile to be able to be considered during the planning/optimization process

Calculate (Un)loading durations strategy must be “Based on Condition”

The Condition name needs to be entered in the Condition for Loading/Unloading Duration field. Determination Strategy must be Freight Unit Dependent.

Now, Freight units can be planned via the optimizer

Check loading and unloading times on Freight Unit Level

Unloading for FU# 4100547047 took approximately 17 minutes.

2976 LB *0,36 = 1071.36 seconds = 17.856 minutes

BRF+ Loading and Unloading Duration can be calculated in this way, based on client requirements.

In conclusion, BRF + Conditions offer flexibility on certain SAP functionalities, which helps businesses to execute logistics operations with respect to business rules without any enhancement.

Some potential benefits for the client are:

Even with the most complex requirements that go outside of the most preferred standard functionalities, SAP TM offers different ways to respond to these complex requirements without ABAP code enhancement. That is where consultancy knowledge gains importance. Creating a custom ABAP code will save the day but it might bring more complexity for future integrations or requirements. After analyzing the customer needs, the best solution needs to be offered to the customer that minimizes the cost, extra work time, and complexity of the implementation. In our case, BRF + conditions would be the best and the most optimized solution. ArchLynk as your supply chain partner is always focused on the best and the most effective solutions via consultants with the right and varied skill sets. To know more about our consulting solutions schedule a demo with us.